Weighing instruments in chemical industries

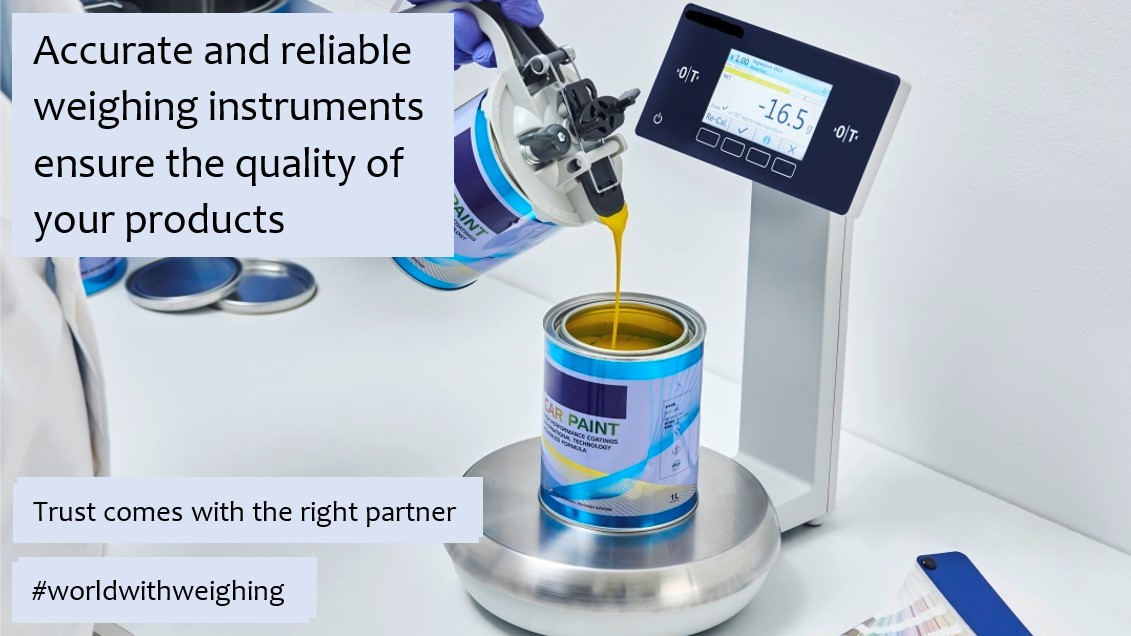

Accurate weighing instrument ensuring the quality of production in the chemical industryWeighing instruments in the chemical industry

Today’s industrial world is continuously evolving. High speed automated processes have long been a standard in most industries and require technologies that can match these needs accordingly. In the area of chemical weighing, this is especially crucial. These weighing instruments are essential for guaranteeing continuous and accurate high-quality output. Without them, bulk materials or cargo items could not be processed with consistent quality and quantity.

Why is quality weighing important in the chemical industry?

The chemical industry has a highly versatile product range. It covers both bulk materials and cargo items. As such, weighing systems must fulfil a variety of different demands.

For bulk materials, weighing-precision is fundamental in providing the right amount to achieve the ideal formula for high-quality output. Each industry and bulk material is different. High-precision weighing instruments ensure steady quantity and quality of every type of bulk material. While weighing precision for cargo items is important for consistent quality, safety also plays an essential part. For instance, weighing systems for cranes or vehicles ensure they are not overloaded and as such significantly reduce the safety risks for the plant and its surroundings.

The continuous processes in the chemical industry make it important that the weighing instruments continue to work. Quality weighing instruments tend to be more durable and reduce chances for production disruptions, particularly in harsh conditions. At the same time, if there are problems a quality weighing partner will find an appropriate solution in a reasonable timeframe.

What are the innovations regarding weighing instruments in the chemical industry?

Chemical weighing instruments are constantly being improved to meet the high demands and the growing complexity of the modern industrial world. Digitalisation plays a crucial role: Examples such as artificial intelligence, big data analysis, augmented and virtual reality will become an integral part of automated weighing processes.

With the help of digital solutions, weighing instruments will boost their reliability, improve safety and plant availability, or even have a positive impact on the overall energy consumption.